Enhance Your Service Workflow With Reliable Industrial Scales

In today's affordable landscape, the precision of industrial scales plays a pivotal role in enhancing overall business procedures. As organizations look for to maximize effectiveness, comprehending the different types of scales and their technical innovations comes to be necessary.

Value of Accurate Evaluating

Precise weighing is crucial in various commercial applications, as also minor discrepancies can lead to substantial economic losses and functional ineffectiveness. Industries such as manufacturing, logistics, and food handling depend upon accurate measurements to make certain product quality, governing conformity, and optimal source administration. Incorrect weights can cause overflow, wastage of raw products, or insufficient supply, impacting productivity and client complete satisfaction.

Moreover, exact weighing is crucial for security and environmental conformity. In the chemical market, inaccurate measurements can lead to improper combinations, resulting in dangerous scenarios or legal implications. In addition, in the food industry, exact weighing is important for sticking to nutritional labeling demands, making certain that consumers get exact information relating to the products they purchase.

The combination of dependable industrial ranges not only improves operational performance but also sustains data-driven decision-making. Companies that focus on exact considering can maximize inventory monitoring, simplify supply chains, and decrease prices connected with returns and rework. Therefore, buying high-grade industrial evaluating services is vital for businesses aiming to maintain a competitive side in today's vibrant marketplace. Exact weighing inevitably functions as a structure for operational excellence and sustainable growth.

Kinds Of Industrial Scales

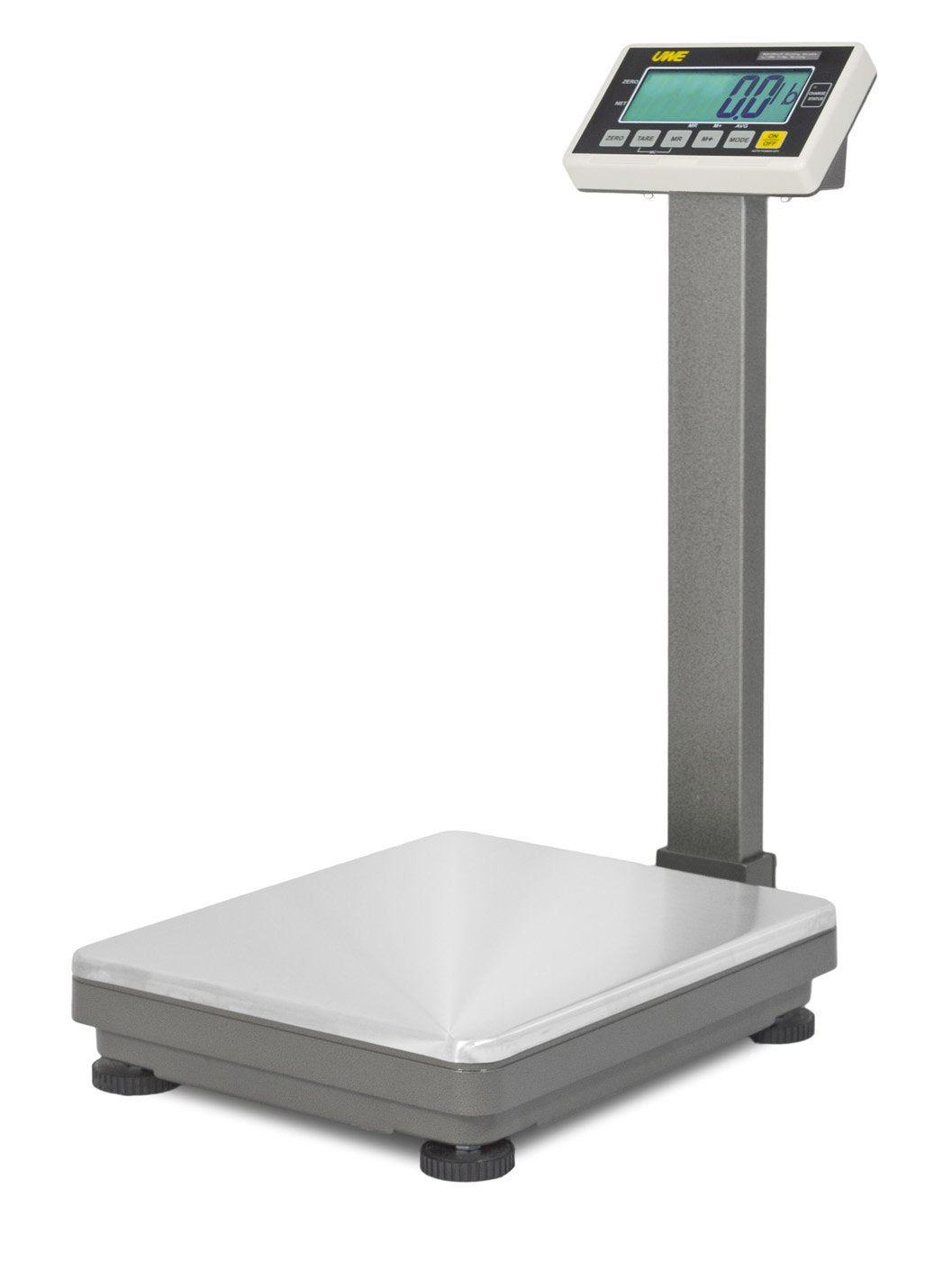

Industrial scales come in various kinds, each created to meet specific considering requirements across various markets. Among the most usual types are system ranges, which offer a large considering surface suitable for hefty items, making them excellent for warehouses and making facilities. These scales usually feature electronic screens for easy analysis.

An additional kind is bench scales, which are generally smaller sized and portable, perfect for use in labs or retail environments. They permit quick dimension of smaller things while preserving accuracy. For applications requiring the weighing of fluids, storage tank scales are specifically created to measure the weight of tank, guaranteeing specific stock monitoring.

Furthermore, flooring scales are used for considering heavy lots on the ground level, commonly made use of in shipping and receiving divisions. Crane scales are likewise significant; they are suspended from a structure to consider heavy materials in commercial setups. Finally, tons cells play an essential duty in many scales, transforming force into an electric signal for accurate weight measurement. Each kind of industrial scale offers a distinct objective, improving functional performance across diverse industries.

Benefits of Modern Innovation

In addition, contemporary industrial ranges usually come furnished with connection features that enable seamless assimilation with various other systems, such as inventory administration and manufacturing monitoring. This interconnectivity cultivates a more cohesive workflow and lessens downtime, as businesses can keep an eye on efficiency metrics and make data-driven choices without delay.

Additionally, many contemporary scales use customizable setups and easy to use user interfaces, enabling drivers to adjust their tools for specific operational needs. Enhanced resilience and durability against harsh environmental conditions additionally add to the durability and dependability of modern-day ranges, ensuring they can withstand the roughness of commercial usage.

Picking the Right Devices

Various markets might require unique kinds of ranges, such as floor scales for heavy loads, bench ranges for smaller sized products, or mobile ranges for adaptability. Additionally, considering the environment in which the scales will be used is vital. As an example, devices made use of in rough atmospheres might need to be resistant and tough to dust, moisture, or extreme temperature levels.

Another vital variable is the innovation made use of in the ranges. Digital ranges often offer advice enhanced precision and convenience of usage, while analog ranges may be enough for less demanding applications. In addition, it is necessary to assess the scalability of the devices, making sure that it can fit future growth or changes in manufacturing procedures.

Lastly, companies need to take into consideration the track record and dependability of producers, as buying top notch equipment can lead to lasting price savings and boosted operational efficiency.

Upkeep for Durability

Normal maintenance is essential for guaranteeing the durability and optimal performance of commercial scales. An organized technique to maintenance not just expands the life of the devices but also assures precise dimensions critical for functional effectiveness.

Begin with routine evaluations to determine wear and tear, making sure components such as lots cells and screens work correctly. Calibration checks must be performed regularly, preferably after significant modifications in ecological conditions or adhering to hefty usage. Exact calibration is vital for conformity with sector criteria and for maintaining the dependability of weight dimensions.

In addition, it is suggested to establish a maintenance schedule that tape-records each service see, calibration, and any kind of repairs performed. This documentation aids in tracking devices efficiency and preparation for future upkeep needs.

Lastly, training staff on proper usage and care techniques will minimize the likelihood of operator error, further enhancing scale reliability. By focusing on normal upkeep, organizations can make certain that their commercial scales remain a dependable asset in their procedures.

Final Thought

In summary, the assimilation of trusted industrial ranges is necessary for enhancing organization operations throughout various fields. Routine upkeep and training additional add to the durability and precision of these scales, cultivating data-driven decision-making and eventually sustaining overall organization success.

Industrial scales come in numerous types, each read the full info here created to meet certain weighing requirements across different fields. Crane scales are additionally noteworthy; they are suspended from a framework to weigh hefty products in industrial setups.Various markets may call for distinct kinds of ranges, such as floor scales for hefty loads, bench scales for smaller sized items, or portable ranges for adaptability - Industrial Scales. Digital scales commonly offer improved precision and ease of use, while analog scales might suffice for less requiring applications.In recap, the combination of dependable industrial scales is crucial for enhancing business procedures throughout different fields

Comments on “Advanced Features of Modern Industrial Scales for High Performance”